In the comments sections of recent humidor reviews, there’s been a debate about the use of medium-density fiberboard (MDF) in humidors, especially the use of MDF in more expensive humidors. MDF is a composite material that combines wood with binding agents; it can then be formed into specific shapes at scale. MDF is everywhere, and most wooden humidors I’ve seen use MDF for the core structure, while a finish is applied to the outside and some amount of Spanish cedar—or in rare instances, Okoume—is applied to the inside of the humidor.

I’ve been told that MDF presents a number of advantages for humidor makers. It’s oftentimes, but not always, more cost-effective than wood, it’s easy to find, and it can be much more stable than hardwoods, meaning it’s less affected by things like changes in ambient temperature, atmospheric pressure or humidity. That said, I understand the point raised by some commenters: if you use MDF to make a humidor, should the humidor be called a wooden humidor?

I don’t know of many companies that use only hardwoods for the humidors, and most of the solid wood humidors tend to be pretty obscure and often expensive options. One of those obscure options comes from American Chest Co., which is notable because its products are made in America by the Amish.

WHAT IS IT?

American Chest Co. was founded by David “Mac” McLoughlin, who has decades of experience in the fine silver business, including as the president of Eureka Manufacturing Co., which was owned by Reed & Barton and made the chests that silverware would be stored in. While there, he collaborated with J.C. Newman to produce the Diamond Crown Humidors by Reed & Barton. Eventually, Reed & Barton opted to outsource the making of the chests to China, which shut down Eureka. That led McLoughlin to found American Chest Co., which makes wooden chests for silverware, jewelry, guns and humidors.

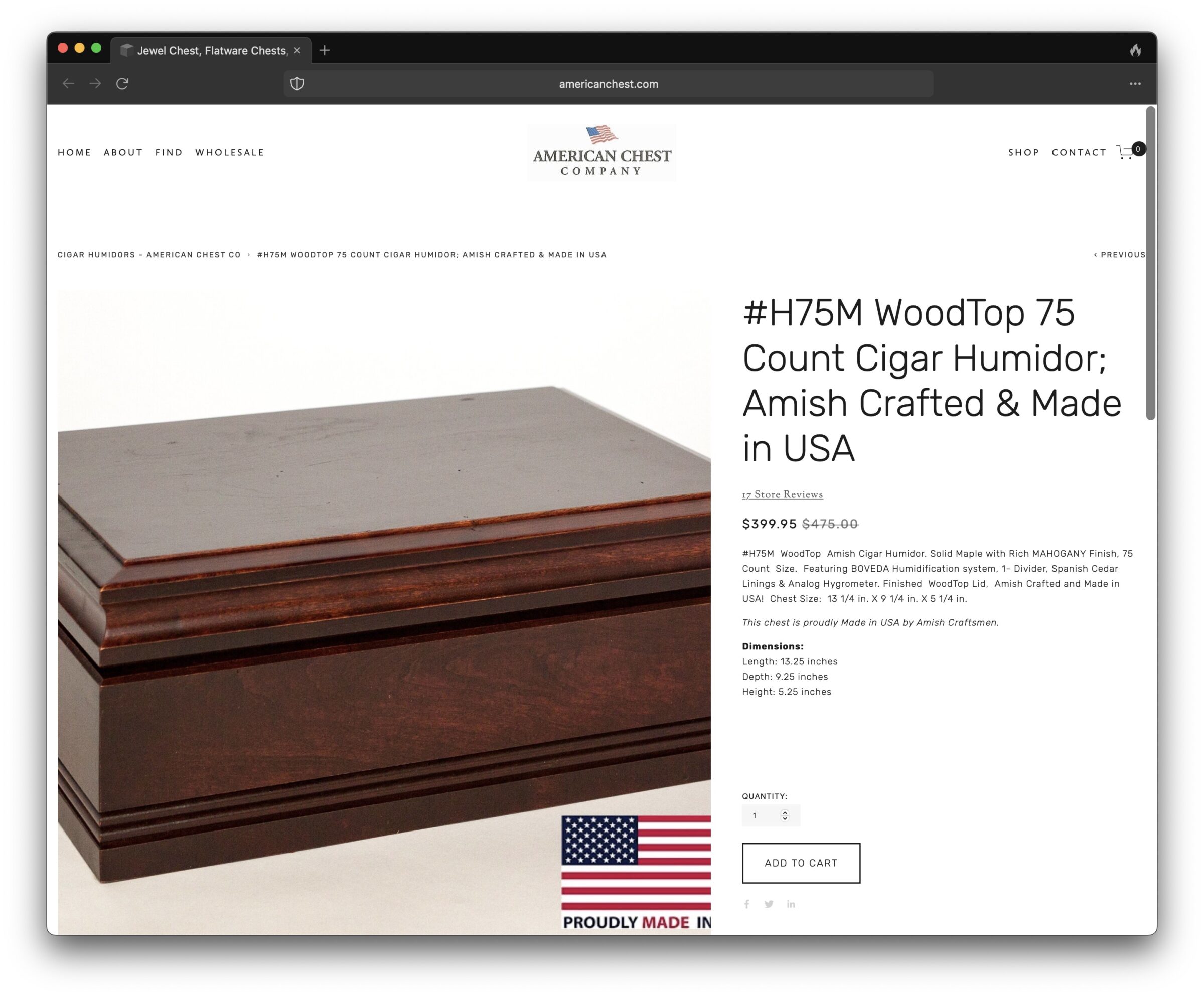

The WoodTop 75 Count Cigar Humidor is the company’s sole humidor design—and looks pretty similar to the aforementioned Diamond Crown Humidors by Reed & Barton—offered in three different finishes. On the outside, each humidor measures 13.25 inches x 9.25 inches x 5.25 inches. All three models are made of solid cherry hardwoods with solid Spanish cedar on the inside. I measured the cherry wood thickness to be around .625 inches thick, while the interior Spanish cedar pieces came in at .325 inches.

While there’s plenty of Spanish cedar in the bottom of the humidor, the WoodTop name refers to the fact the inside of the lid does not have Spanish cedar. Instead, it has the same stained cherry wood as the exterior, which creates an interesting look.

HOW MUCH DOES IT COST?

All three humidors are listed at $475, though that doesn’t seem to be the street price.

As of August 2023, the American Chest Co. website lists the three humidors at:

- Heritage (Cherry) — $369.95

- English Walnut — $399.95

- Mahogany — $399.95

We paid $399.95 for the English Walnut finish in October 2022.

WHAT’S INCLUDED?

- The Humidor

- One Analog Hygrometer, attached via velcro

- One Boveda Holder, attached via magnets

- Removable Spanish Cedar Divider

- Two 60-gram Boveda Seasoning Packs

- Two 60-gram Boveda Packs

HOW LARGE IS IT INSIDE?

I measured the interior of the humidor at 11.25 inches x 7.5 x 3.925 for a total volume of 331.17 cubic inches. Per Humidor Discount’s humidor calculator, that is enough to hold 60 robustos if you maximize the space.

WHAT MAKES IT SPECIAL?

It’s made by Amish craftsmen. I’m not sure how much that matters, but it’s certainly a unique selling point.

HALFWHEEL’S HUMIDOR TESTING PROCESS (2022 REVISION)

Last year, I updated the testing procedures used for humidors. Each humidor goes through a standardized testing process for seasoning, use with Boveda packs, use with the included humidifier and a test in a dry cabinet to evaluate the seal.

Measurements are taken via a scale, two SensorPush devices and a moisture meter.

Ideally, each humidor follows this standardized process:

- Boveda seasoning packs for 14 days (Weigh before and after, use moisture meter before and after.)

- Boveda packs for 13 weeks (Weigh before and after, measure with moisture meter after.)

- (Optional Reseasoning)

- Included humidifier for eight weeks (Optional refill at 28 days, measure with moisture meter after.)

- (Optional Reseasoning)

- Two weeks inside of the dry cabinet. (Measure with moisture meter after.)

For this humidor, the optional reseasoning processes were not needed. Furthermore, the included humidification is Boveda, so Step 4 was also skipped.

During each of these steps—with the exception of the optional refill during the included humidifier part—the humidors are closed. The only times a humidor is opened are when I’m moving from one step to another and need to switch out the humidification elements, and when I use the moisture meter. In addition, the humidors are pretty much empty during these tests. Inside are the two SensorPush devices, the humidification element(s) and the included dividers and/or trays, but no cigars or anything else.

Per Boveda, I’m told that for every 200 cubic inches of volume, you should use one 60-gram pack and to round up to the nearest 200 cubic inches.

SEASONING

I use a moisture meter during the testing procedure to measure how much moisture content is in the wood. For me, this is helpful because it provides relatively objective data about what is happening inside of the humidor’s material and not simply the air inside of the humidor. It’s especially helpful during seasoning when the moisture meter can let me know if the humidor is actually absorbing the moisture that the Boveda packs are putting out.

Most of my experience using the moisture meter has been using it with MDF and Spanish cedar veneers. As such, I didn’t realize how much further into the solid Spanish cedar I would need to penetrate with the prongs of the moisture meter. The first couple of times I tried using the moisture meter on this humidor, I didn’t get results. That led to a delay in starting this testing process before I realized I just needed to push deeper.

With that figured out, the moisture meter registered results and the testing process began. Despite there being a lot more cedar inside than most humidors, the WoodTop 75 seemed in a pretty good place after just two weeks.

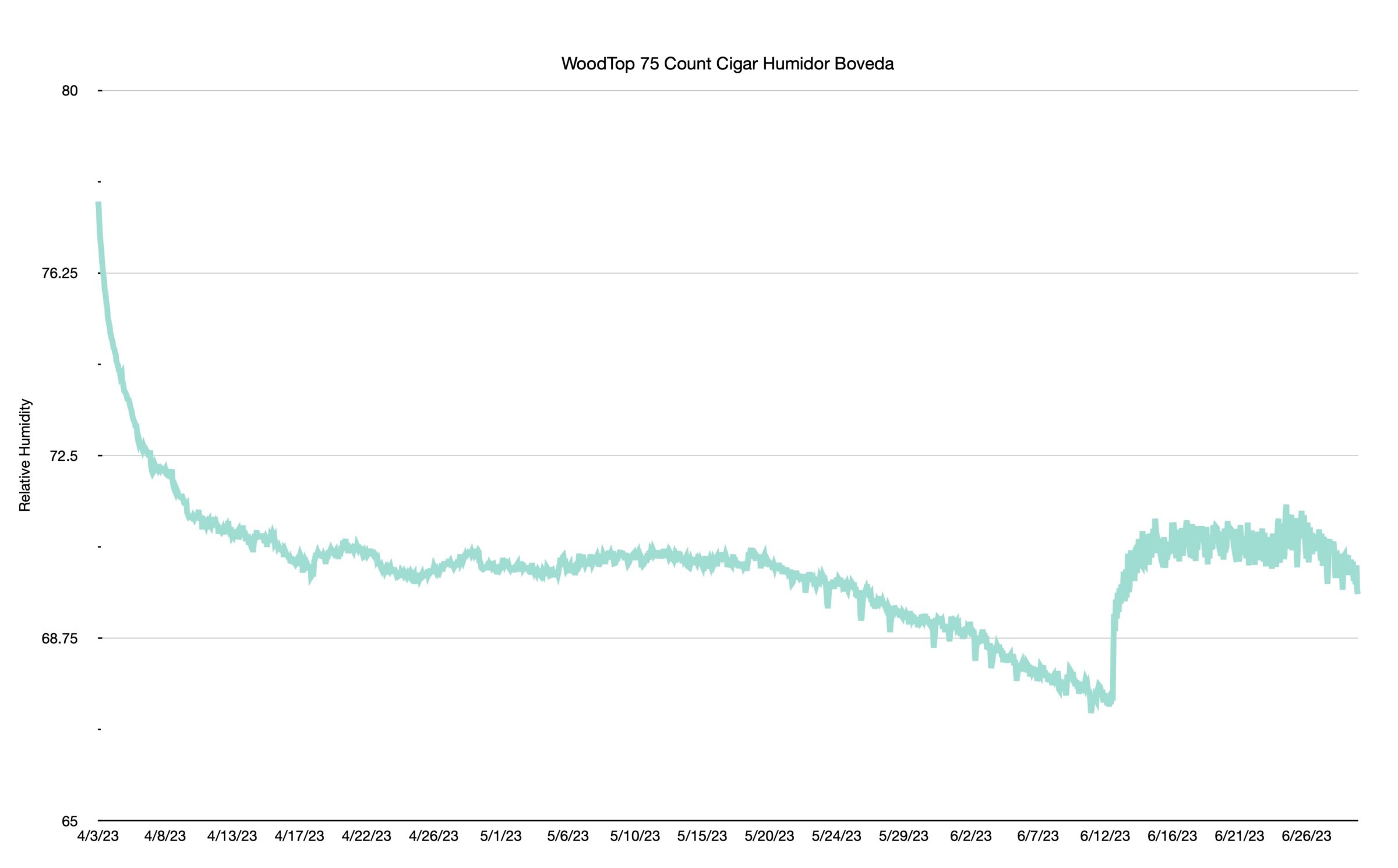

BOVEDA

The above chart shows the relative humidity reading—taken once per hour—during the 13-week Boveda test, when two 69 percent 60-gram Boveda packs were placed inside the humidor. The data is very good, albeit a bit weird. I’m pretty sure that around June 12, I pushed down the lid of the humidor—more on this below—which created for a better seal and explains the uptick in relative humidity. I didn’t add new packs or anything like that, but the sudden rise in the humidity is an odd one.

This chart might actually be the better one, it shows the frequency of the relative humidity. What you can see is that it spent more than 60 percent of the time registering a relative humidity between 70-70.99 percent relative humidity.

Because the Boveda packs (+/- 2 percent) and the Sensor Push devices (+/- 1.5 percent) have accuracy ranges, I’m more concerned with the consistency of these numbers than I am with how close to 69 percent the numbers are.

INCLUDED HUMIDIFIER

The WoodTop 75 comes with Boveda packs as the included humidifier, so this part was skipped.

DRY CABINET

This is a pretty good result for the two-week dry cabinet test, though it doesn’t tell the full story.

Given the issues with the seal—more on that in The Bad section—I suspect that the thick pieces of solid Spanish cedar ended up functioning like humidors of yesteryear. Humidor technology has developed in a way that I think is similar to sailing boats. For a long time, wind was the best option to move a boat, so boats relied on their sails. Obviously, motorized propulsion is now the more common solution, though some motorized boats still have sails.

Humidors were once like that. Before the days of Bovedas, beads, gels and electronic humidifiers, humidors relied on cruder forms of humidification—a damp cloth in a small jar was oftentimes used—meaning that the porous Spanish cedar inside of a humidor was often going to play a role in the humidification of your cigars. Nowadays, advanced humidification options placed inside of an airtight container can provide excellent storage for your cigars.

By the time the WoodTop entered the dry cabinet, the seal was no longer flush, though not with a visible gap at the front of the humidor. That said, I doubt the box itself was fully closed like it was intended to be. Despite the issues with the seal, the humidor still would have kept cigars in relatively decent condition for the two weeks of the dry cabinet. I suspect that if this humidor used Spanish cedar veneers like most humidors, and therefore had much less Spanish cedar inside, this would have gone much worse.

THE GOOD

- The Humidity Data is Very Good — The data from both Sensor Push sensors is remarkably similar and shows the same thing: this would have kept my cigars humidified throughout the testing process. This data is conclusive but might be surprising given the eventual issues with the humidor’s seal. The issues with the lid not appearing flush didn’t seem to start until the second half of the Boveda test and the visible gap wasn’t noticeable until after the testing process was complete.

- The Interior Looks Great — With the exception of the Boveda holder, which is made using a much lighter-colored wood than the rest of the lid features the same wood as the exterior, hence the WoodTop name. I really like the look inside, it’s decidedly different than most humidors.

- Woodworking Details — While I have some gripes about the finish, the woodworking of the humidor is substantially better than most humidors. There are a lot more milling and other woodworking terms that I do not know. Unlike most humidors which tend to be rectangular boxes with some rounded edges, there are a number of very defined features such as the top of the lid, the edges of the lid and the stripes that run toward the bottom of the humidor.

- Solid Spanish Cedar — Similar to the above, the use of thick Spanish cedar—for whatever it’s worth, those interior pieces are removable—lets me know what I’m paying for. This is different than most humidors and it’s nice to be able to see why the humidor costs more than most of the Chinese-made humidors of similar size.

- It’s a $400 American-Made Humidor — While some Etsy sellers might offer humidors for less money, most of the commercially-available American-made humidors are going to be more expensive than this. For context, Daniel Marshall has an as-is model that is slightly smaller than this listed for $495. If you are interested in buying an American-made humidor, this will likely be one of the least expensive options.

THE BAD

If you would like to understand the issues with the lid and hinges, please watch the video above.

- The Humidor Developed a Visible Gap in the Front — During the testing process, I noticed the lid no longer appeared to close in a flush manner, but that was just the start of the problems. After the testing process was complete, the lid not closing flush issue turned into the humidor having a .17 inch visible gap, meaning that a decent-size house fly could probably fly in and out of the humidor if it wanted to visit the cigars inside. The above picture shows the humidor with the lid “closed,” albeit with a flash light inside to help get around the shadows by the gap.

- The Hinges Seem to be the Culprit — In addition to developing an issue with how the humidor closes, the angle of the lid’s opening also changed. Above is a picture of the humidor shortly after it arrived last year, you can see the humidor opens a bit beyond 90 degrees, which is pretty standard. As shown throughout the video, the humidor now opens up more or less 180 degrees.

- This seems to be related to the hinges, which are just not up to modern humidor standards. I went and looked at a half dozen less expensive humidors we have in the office and found that most of those humidors use hinges inside of the sides of the humidor, which can help to stabilize the lid when opening and closing, but also prevent the humidor from swinging open too wide. The one humidor that didn’t have this used a much beefer piano hinge.

- This humidor uses pretty simple metal hinges with nothing integrated into the sides of the humidor, meaning that these hinges can be bent. Even if you aren’t intentionally bending it, the weight of the lid is going to do this over time.

- What makes this issue so much more glaring is that in the roughly 10 months I’ve owned this humidor, it’s likely been opened no more than 100 times, which is far less than I imagine most people reading this site would open and close their primary humidor.

- Beyond the issues with the lid closing flush, the extremely wide opening was annoying as opening the humidor would send the lid crashing into whatever was behind it. Even when opening the humidor carefully, it meant the lid was going to rest on whatever was behind the humidor.

- The Visible Gap Was Fixible — The good news is I was able to fix the visible gap. I loosened the Phillips screws on the back of the humidor—there are four per hinge, so eight total—and then retightened them, which removed the visible gap. It still left the lid in a place where it wouldn’t close flush, though I could achieve a flush seal if I wanted. Loosening the screws even more would get the lid to close flush, but it created for a wobbly lid upon opening and closing. I ended up trying to find a happy medium, though even that wasn’t perfect.

- This is Not an Isolated Instance — I was surprised to see that this picture on American Chest’s website shows the same issue.

- The Boveda Holder Detaches From the Lid — While I didn’t open and close the humidor that much, most of the time I opened the humidor, the Boveda holder was no longer sticking to the lid. I only put one Boveda pack in here, which isn’t enough for this size humidor, and it still became detached. I have this issue with most Boveda holderst that require me to stick a magnet or metal plate to the inside lid of the humidor, so perhaps it’s user error. An integrated metal plate would solve this issue, but that creates an issue for this style of solid wood humidor.

- Nicks, Scratches & a Staple — This humidor has lots of minor imperfections, including many that seem manmade. There are tiny holes that look like a nail might have penetrated the wood, scratches, more aggressive scratches that removed more than just surface amounts of wood and even a visible staple. It’s not a completely refined product, but I’m generally fine with all of it, short of the visible staple. Part of the experience here is that it uses real wood and that wood is going to tell a story. That said, if you want a perfect humidor, this isn’t it.

THE COMPETITION

The obvious competitor is Waxing Moon, a Minnesota-based maker of humidors that also uses solid woods instead of MDF. Waxing Moon is a very different humidor maker because it generally makes customized humidors, but its smaller humidors start at around $550 and go up from there.

I reviewed a Waxing Moon humidor earlier this year and had issues with how that humidor struggled to close flush, though that humidor’s issue ended up creating a problem that made it difficult to open the humidor. While I suspect that it would end up being close to double the price, I’d get a Waxing Moon over the American Chest Co. because Waxing Moon can theoretically build your ideal humidor. I also find the Waxing Moon fit and finish to be a lot better than the American Chest.

Other Competitors

- Diamond Crown Havana Collection Humidor ($365) — Some of halfwheel’s most expensive cigars are stored today in this humidor. The Havana Collection may not be the absolute best humidor I’ve ever used, but it’s more than enough to store cigars properly over time. You are foregoing the American-made, solid wood nature, but I think you are getting a humidor that is easier to live with. I’d recommend the Havana Collection over the WoodTop 75. Note: the price is the MSRP at the time this humidor was reviewed.

- Savoy Executive Medium ($435) — The Savoy Executive line has long been my most recommended humidor, particularly in regard to value. This is a humidor that should last you for the rest of your life but won’t break the bank. This is not made in America and does not use solid wood, but it’s a very refined product at what I consider to be a fair price. I’d recommend the Savoy over most humidors, including the WoodTop. Note: the price is the MSRP at the time this humidor was reviewed.

- Daniel Marshall Ambiente 125 ($495) — The lower-end Daniel Marshall Ambiente is the same interior you get on a higher-end box, but with a matte finish. It’s American-made and larger than the WoodTop. I’d take the Daniel Marshall over the WoodTop 75, though it’s close.

- Colibri Heritage Humidor ($495) — This is a larger humidor that is not made in America and does not use solid woods. That said, it’s going to store more cigars and appears to be a more refined product. Most importantly, I think this humidor will be easier to use. I’d recommend the Colibri Heritage over the WoodTop 75. Note: the price is the MSRP at the time this humidor was reviewed.

SHOULD YOU BUY IT?

No. This is the second review in a row of an American-made humidor that uses solids woods instead of MDF. In both cases, I admire the craftsmanship but struggle with whether these humidors are easy to live with as an owner. The WoodTop 75’s hinge issues make for real problems. It’s annoying that the lid will crash into the wall or whatever’s behind the humidor, but what it does to the seal of the humidor is a fatal flaw. Until American Chest Co. figures out a new solution for the hinges, I cannot recommend the humidor.

The humidor for this review was purchased by halfwheel.