After Wednesday’s adventures, I was eager to put a fresh spin on the 2025 Puro Sabor Festival. Thursday started off with a bit of a schedule switch, as my visit to A.S.P. Enterprises moved from the afternoon to the morning while the visit to Karen Berger’s Estelí Cigars S.A. moved from pre-lunch to post-lunch. In hindsight, it might have been a blessing as the sun was shining brightly and being out in a tobacco field made more sense with a bit of cool morning air still lingering.

We were met by David Perez, ceo of A.S.P. Enterprises, which is one of the most important tobacco growers, processors and brokers in the premium cigar industry. As he told the group, he feels pretty confident saying that if you were to walk into any good retail humidor, you’d find A.S.P. leaves in seven out of 10 blends.

As tobacco is still going in the ground, we were able to start at the very beginning of the process, putting seeds in foam trays so they will germinate and start getting nutrients from day one. Immediately, one of the things that is uniquely A.S.P., at least in my experience, is that they place the filled trays in pools of nutrified water so that it gets pulled up through small holes in the bottom of the tray as opposed to being sprinkled on top and left to drip down.

My group was taken on a step-by-step tour of the process, which culminated in seeing tobacco that had been in the ground for about 70 days and which would start to be harvested on Monday. The only downside to our timing was that there was no tobacco in the barns yet, but fortunately, we saw some at Victor Calvo’s farm on Wednesday.

Being on a tobacco farm like A.S.P.’s reminds me just how much tobacco is being grown, an amount that boggles my mind. For instance, Perez estimated that the company’s Nicaraguan farms, which only produce filler, will generate about 1.2 million pounds of tobacco in the upcoming harvest. That number is hard to wrap my head around, and then I remember that it’s one type of tobacco grown on one farm in one region of one country.

From there, it was onto pre-industry, where the tobacco processing happens. It’s the fairly typical process of sorting, fermenting, dehydrating, rehydrating, etc. But there were some unique things that A.S.P. does that I can’t recall seeing elsewhere.

First, they use two styles of pilones: the first is what I would call the traditional method of stacking rows of what are called hands of tobacco, several leaves tied up at the base of the stem. The other is a loose leaf design, where individual leaves are simply stacked on top of each other. There’s a distinct trade-off between the two methods: the traditional method reduces breakage, while the loose leaf version is said to be better for fermentation and airflow but results in more broken leaves. Given that all the tobacco that is being grown by A.S.P. in Nicaragua is filler—its wrappers come from Ecuador—the company can allow a bit higher tolerance for breakage, but it still has to be within limits.

Second, they offer a warranty on their tobacco. Perez said that if a client is unhappy with the leaves for whatever reason, they can call him and arrange for a return. He said it’s only happened twice in his tenure, with one instance being because a company grossly misjudged its needs and overbought, then found itself sitting on tobacco it simply wouldn’t use.

Third, the company has a graveyard of old, Russian-made tractors on a small plot of land inside its pre-industry facility, right between the administrative offices and the main work area. Perez pointed this out with pride, as while the machines themselves no longer function, they serve as parts donors for others that do. These hunks of metal sit in the sun, their best days clearly behind them, but their usefulness seemingly indefinite.

With the A.S.P. visit wrapped up, it was off to lunch at one of Plasencia’s farms, which I believe has hosted a lunch every year that I have been to Puro Sabor. While we’re not sitting among tobacco plants or inside of a barn, it’s a really lovely setting, lush with flowers, grass and other vegetation, and one of the most idyllic settings of the trip.

Upon arrival, we were handed a Plasencia Alma Fuerte to smoke, as well as a cowboy-style hat from one of the event’s sponsors. Given that my head does not fit into the one-size-fits-all category, I passed on that.

I know that there are people reading this who want a detailed report on the food menu; regrettably, I’m not a food critic nor even an advanced amateur in the culinary arts, so all I can say what that it was enjoyable. Ga

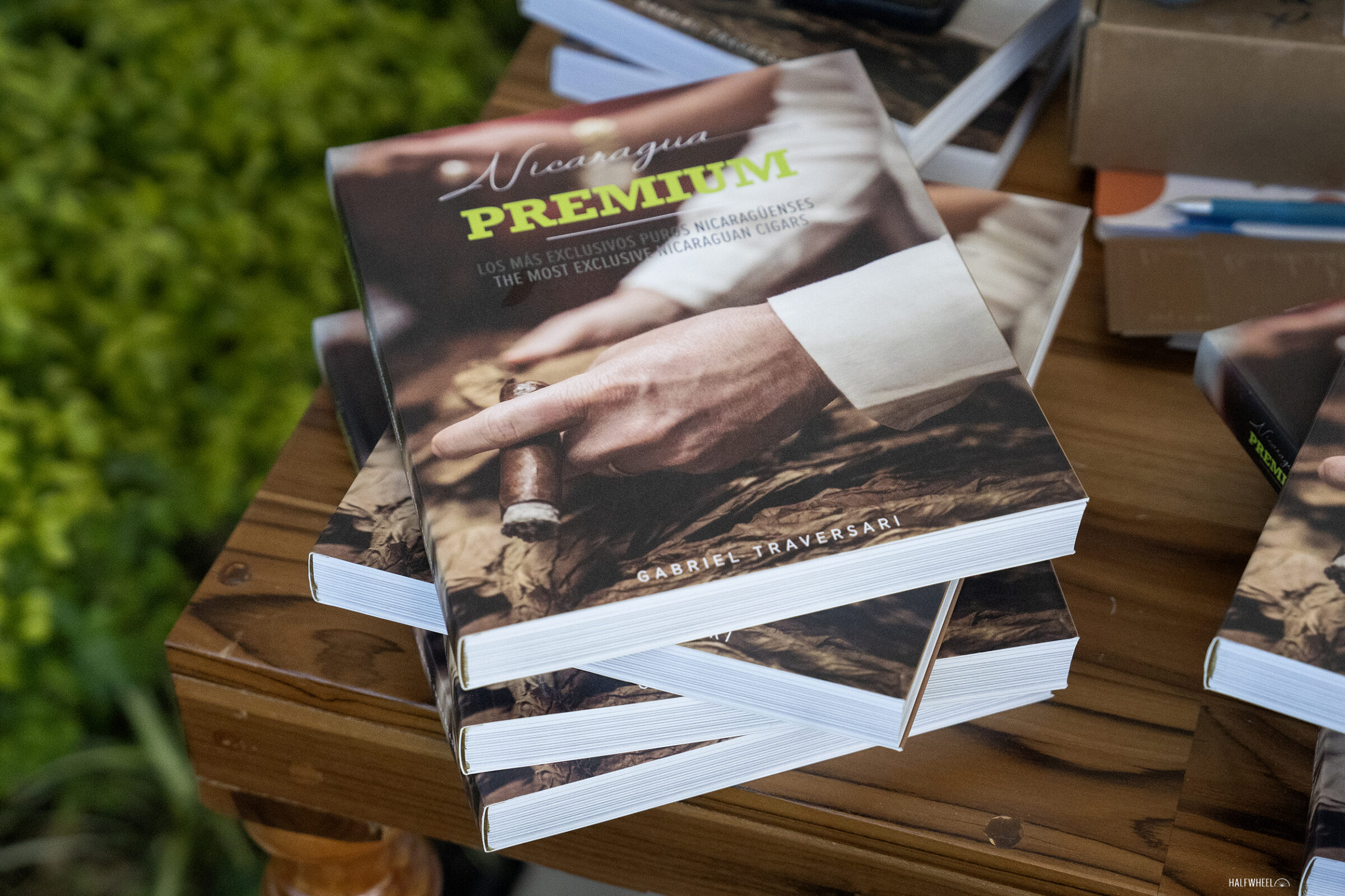

Beyond just the food, cigars, wine from Epifania and some music, there was also the launch of a new book about Nicaragua’s cigar industry. It’s called “Nicaragua Premium” by Gabriel Traversari, a Nicaraguan-American actor, director, writer, singer, songwriter, painter and photographer. As the festival was the soft launch of the book, I picked up a copy and look forward to reading it soon.

After lunch, it was time for a visit to Estelí Cigars S.A., the home of the K by Karen Berger brand. It’s a somewhat unassuming factory from the outside—signage notwithstanding, of course—but the inside is quite interesting. The three-story building is a former hotel, and the company kept a boutique hotel feel to it, complete with individually numbered doors, wonderful wall art and other decorations to make it feel less like a cigar factory. It reminded me a bit of the De Los Reyes factory in the Dominican Republic, which uses a similar theme for its facilities.

Berger and her staff were very welcoming from the get-go, and while Drew Estate needed a hurried approach, Berger’s facility merited a more relaxed pace. There was an area of the main level that had several rocking chairs, while the staff offered us a choice of coffee, Coca-Cola, water, Flor de Caña rum, and Toña beer, along with some small pastries to enjoy while a mariachi band played.

Estelí Cigars S.A. is one of several cigar companies that operates multiple facilities and with a distinct split; the first is the farm and pre-industry, which handles the growing and processing of tobacco. While I haven’t seen the full scale of the operation, I did get to somewhat visit the farms by way of a lunch during the 2024 festival.

The factory handles the parts of the cigar-making process that happen once the tobacco has been unpacked from the bales and is ready to be made into a cigar, followed by the first round of aging that involves the cigars shedding moisture from the rolling process before heading to banding and packaging.

The fairly small size of the factory is a fairly stark contrast to both Drew Estate and A.S.P., which are quite large operations. During our visit, there were about 10 pairs of bunchers and rollers working, with space for about four more pairs judging by the open tables, a total that is probably less than one row in one of Drew Estate’s rolling rooms.

While the size of the facility may be quite different, the process is largely the same. In this case, tobacco comes in more or less ready to use, then it gets handed off to the bunchers and rollers to make the cigars, which then get inspected for quality control before heading to the aging room for some rest, then onto packaging before being packed up.

Speaking of the aging room, Berger was incredibly generous, telling members of the group to look around and if they found something of interest, to simply grab one. While seemingly every other aging room I’ve been in has been inventoried up and down, front to back, and cigars were certainly not to be removed, this approach was quite different.

Once the tour was wrapped up, it was back to the hotel for a quick clean-up before the White Party at Oliva’s El Fumador facility, which I visited in 2024 and which handles a lot of the company’s pre-industry operations.

Fred Vandermarliere, ceo of Oliva Cigar Co., delivered the welcoming remarks and encouraged everyone to enjoy the evening.

The other cigar moment, as they are called, was introduced by Pedro Gomez, brand ambassador for Drew Estate. Gomez was born and raised in Estelí and took a moment to recognize all of the people from the city and its surrounding region who make premium cigars possible.

As the name suggests, attendees are asked to dress in white, and this is definitely a party, with a mix of live music and a DJ getting people dancing after dinner. The party wrapped up sometime after midnight, with a good number of folks choosing to conitnue the celebration into the early hours.

Friday has a bit of a schedule revision to it; what had originally been scheduled to be a day at AJ Fernandez with a “forum” followed by lunch would now be another visit to a factory followed by lunch at one of AJ Fernandez’s farms, with the afternoon free for rest, touring the city or whatever you might be up for. I’m hoping to get in another visit to a factory, but we’ll see if that happens.

Disclosure: Puro Sabor paid for my festival registration, which includes the activities, lodging and most meals while in Nicaragua. My airfare and other incidentals were paid for by halfwheel.