Day two of Procigar started at Casa de Campo and ended in Santiago. It’s the longest day of the week and one that is a series of highs and lows—or perhaps—highs, then lows, then highs.

It started with checking out of Casa de Campo, which goes pretty smoothly considering the size of the group and the relatively early start. After that, it was time to head to Tabacalera de García, the largest cigar factory in the world, best known as the primary home of Altadis U.S.A.

Tabacalera de García is a different kind of cigar factory as it’s really a cigar factory, with emphasis on the latter. This is not the place for artisanal, small batch production. Rather, this is a testament to human engineering, at least in the category of rolling up dry leaves.

The factory also holds the distinction of being the most featured factory on this site as we’ve now visited it for four consecutive years. That admittedly makes the coverage a bit more challenging, so if you want to read more about the factory, you can read our coverage from past years:

One of my favorite features of the tour at Tabacalera de García is seeing the sign outside that documents the number of accidents for the year. This is something the workers pass by each and every time they enter the factory, which seems somewhat odd.

The tour was largely the same, though it started with one notable difference: our shoes. Tabacalera de García is owned by a huge multinational corporation—Imperial Brands, plc—because of that and the various compliance policies at the factory, there are some unique safety measures in place. One of them is that all guests must be in steel-toe boots.

We were told that there are a couple of potential risks, such as the large crates of tobacco being moved or a cigar mold falling on someone’s foot, both of which sounded painful. As such, Tabacalera de García provided boots to everyone attending, which meant it looked like a bowling alley’s worst nightmare.

Once boots were put on, we watched a movie and then started the tour, which followed the same pattern as in years past.

Above is a worker wetting and then shaking wrapper leaves. This is to allow them to be placed on a cigar without breaking. Interestingly, our pictures from prior years seem to suggest that workers used to wear masks for this process.

Above is what is referred to as a “hand of tobacco.” It’s various leaves tied together at the bottom of the leaves.

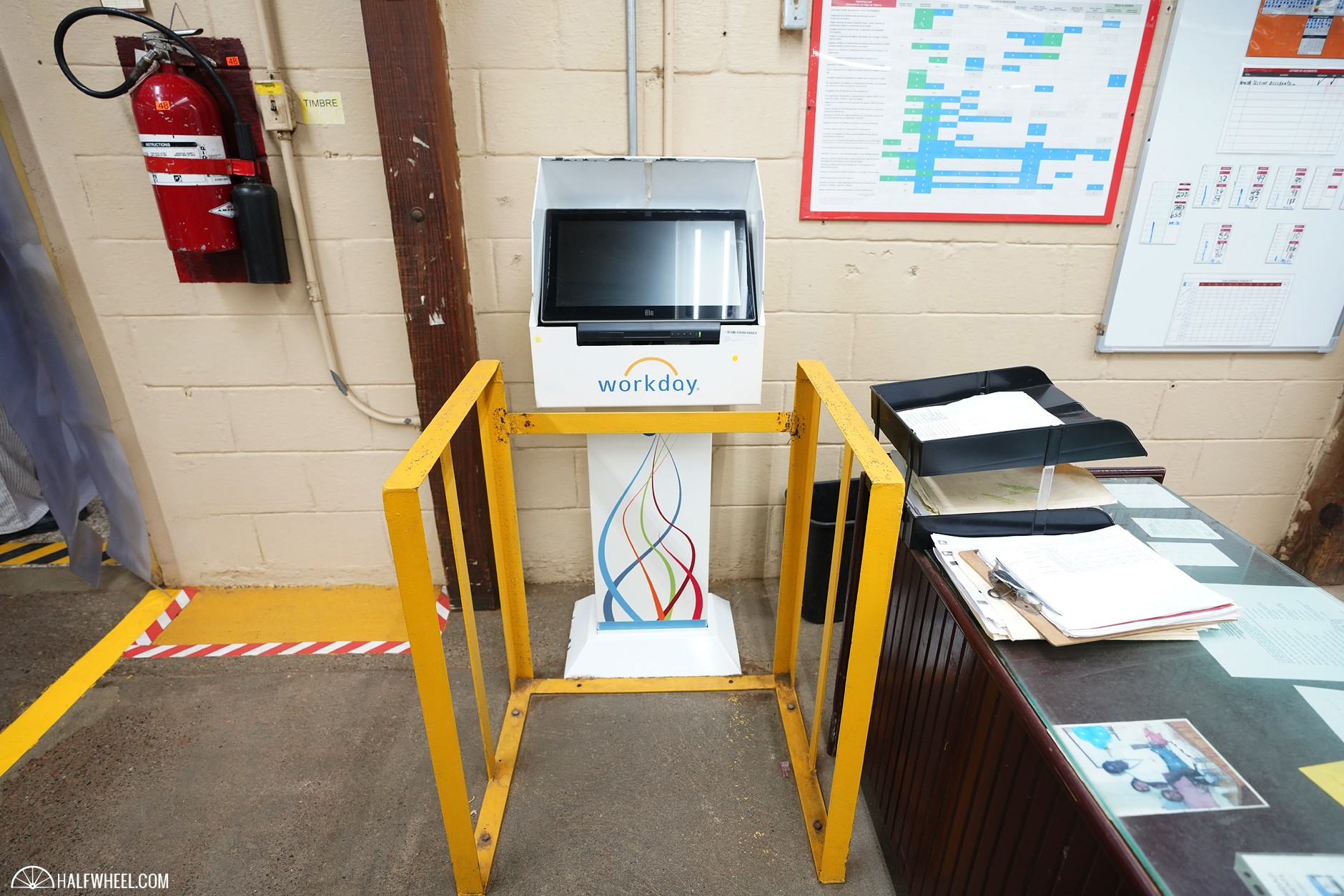

One thing you are unlikely to see in smaller factories is a Workday station. This is an HR tool that allows for workers to keep track of their vacation days, salary and other basic info. Workday has an app that is used by the factory’s office staff, these stands are designed for those workers who don’t have phones or just want to be able to view the info quicker.

Another thing that is rarity is the safety vests. These are only worn by a fraction of the workers—from what I could tell those responsible for moving very big items—but is an overlooked aspect in the grand scheme of TDG.

For the last couple years there has been a prototype factory within Tabacalera de García. This is laid out differently than the rest of the factory and we are told is being used to test potential updates to the floorplan. This year that area included these new massive pressing stations which had hundreds of molds inside of them, something completely different than any other factory I’ve been to.

A supervisor sat perpendicular to a long rolling table that contained dozens of pairs.

I wish that sign said something along the lines of not riding the hand trucks. Unfortunately, it’s telling workers they aren’t allowed to congregate in the area.

After the tour—which once again included much more which you can read about in the links above—we went back to Casa de Campo for a brief lunch. The worst part of Casa de Campo is leaving and it’s particularly tough when you then have to make the 4+ hour drive to Santiago.

A handful of media members—Lisa and Thor Nielsen of Cigar Press, Cigar Journal’s Katja Gnann, Jamilet Calviño of Cigar Snob and Tobacco Business Magazine’s Stephen Ross—opted to hire a driver to make the journey from Casa de Campo to Santiago. Procigar has large buses that make the journey, but we wanted to arrive a bit earlier.

We indeed got to Santiago much earlier in the bus which made the remainder of Tuesday night a lot easier. I got a bit of work done before heading outside to the pool for the annual cocktail hour, which consisted of a couple cigars, some conversation and a lot of Presidente.

For those wondering, tomorrow I’ll be at La Flor Dominicana for its tour, which has probably become the most popular tour of Procigar.

Disclosure: Procigar paid for my registration, which includes lodging and meals.