Last Spring, Brooks Whittington and I visited TABACALERA LA iSLA, a small cigar factory in the Dominican Republic. For many different reasons, all of which are my fault, this post never got published. It’s a bit weird to post this now because at least some of the factory no longer looks like what we saw. For example, while we were there, the windows were being replaced and upgraded. Still, I figure it’s better to publish these than not.

Most cigar factories are just referred to by their names: Tabacalera La Alianza S.A., Fábrica de Tabacos Nica Sueño S.A., Raíces Cubanas, etc. However, there are some factories that are regularly referred to using a formula of person’s name + apostrophe + factory name. Over the last few years, nowhere has that seemingly been more true than TABACALERA LA iSLA. Sorry, I mean, “Hostos Fernández Quesada’s TABACALERA LA iSLA.”

Perhaps it is because of Hostos’ unique name. Perhaps it’s because so many of the people in cigar media met Hostos through his time at Quesada. Perhaps it’s all random.

In late 2020, he announced that he had opened up a new factory in the Gurabo Zona Franca—a free zone—in Santiago, Dominican Republic. By the time we visited in the spring of 2022, the factory had been open for more than a year and had already attracted clients like La Sirena, Matilde and Warped.

LA iSLA is part of a new class of Dominican factories coming from people that have already established themselves in the cigar industry. Hostos spent years at Quesada and then Cigar Rings—a company that makes cigar bands—before opening this factory. Eladio Diaz, the former head of production at Davidoff, launched his own factory—Tabacalera Diaz Cabrera—about a year later and Klaas Pieter Kelner, another Davidoff alumni and also part of the Kelner tobacco family, opened his new factory earlier this year.

For the last decade-plus, most of the energy surrounding new cigar factories has been in Estelí, Nicaragua. While new factories are always opening in the Dominican Republic, few ever have the fanfare like the aforementioned trio. It’s also interesting to see how those three—along with Henderson Ventura’s continued rise—will affect the more established Dominican players.

All the rest of this post is the work of Brooks Whittington. — Charlie Minato.

While TABACALERA LA iSLA is not a huge factory by any means, the complex has space for quite a few more in the future. When we visited, the factory had just 10 pairs, i.e. 20 people making cigars.

Cigar making begins with tobacco. Once the tobacco has been properly cured and sorted, it must be humidified so that it’s pliable enough to roll into a cigar without tearing.

Different blends call for different tobacco. These boxes hold specific tobaccos from the Dominican Republic and Nicaragua.

In the deveining area, a manager makes sure the center stem has been removed from tobacco leaves.

The final step before getting rolled is one last organizational step. The individual leaves are weighed out and placed into bags. These bags will be given to the bunchers with all the different tobaccos they need to produce a certain number of cigars using the blend recipe.

Yes, that’s an 8 x 50 mold.

Rollers use a chaveta to cut the wrapper leaves to size. After the wrapper is applied, the roller cuts out small circular pieces of tobacco to be applied as caps to the top of the cigar.

One of the most important aspects of quality control occurs just after a cigar is rolled, as random cigars are inspected on the rolling floor.

The aging room probably looks a bit different 18 months later. In fact, there’s a good chance most the cigars pictured here have already been turned into ash.

Every bundle of cigars in the aging room gets an enormous amount of information, including who rolled the cigars, when the cigars were rolled and the vitola. There’s both barcodes and QR codes that store the information digitally.

One of the final steps before a cigar is placed in boxes is the application of the cigar band(s). The process is laborious but involves a surprising amount of skill: use too little glue and the bands could fall off, use too much glue and the bands could damage the wrapper when they are removed.

These La Sirena cigars are banded twice: a small, unassuming band is placed on the cigar first, which is then covered by a larger and more intricate band.

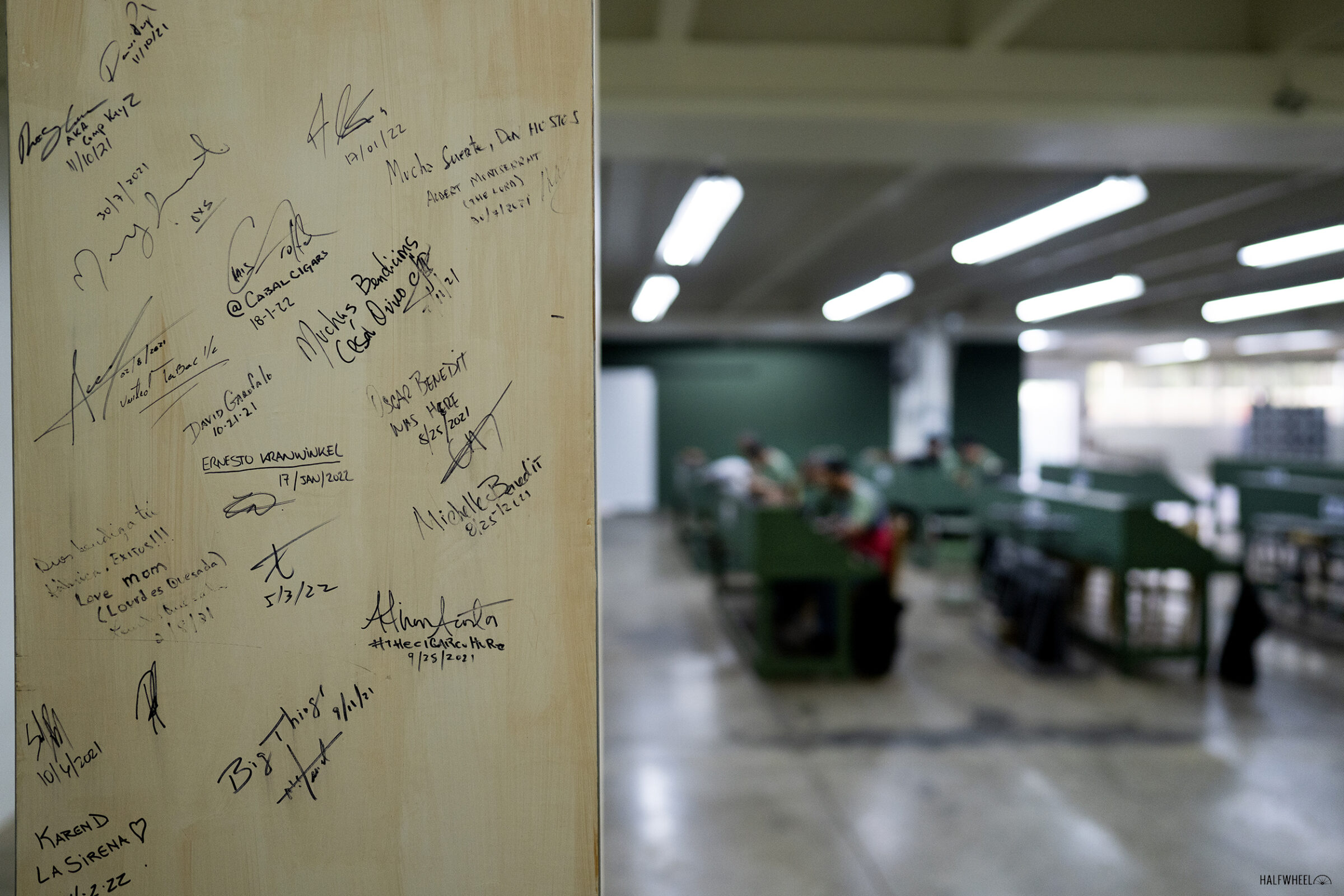

One of the columns on the rolling room floor of Tabacalera La Isla has the signatures of people who have visited the factory. Again, this probably looks very different today.